PLASTICS PROCESSING

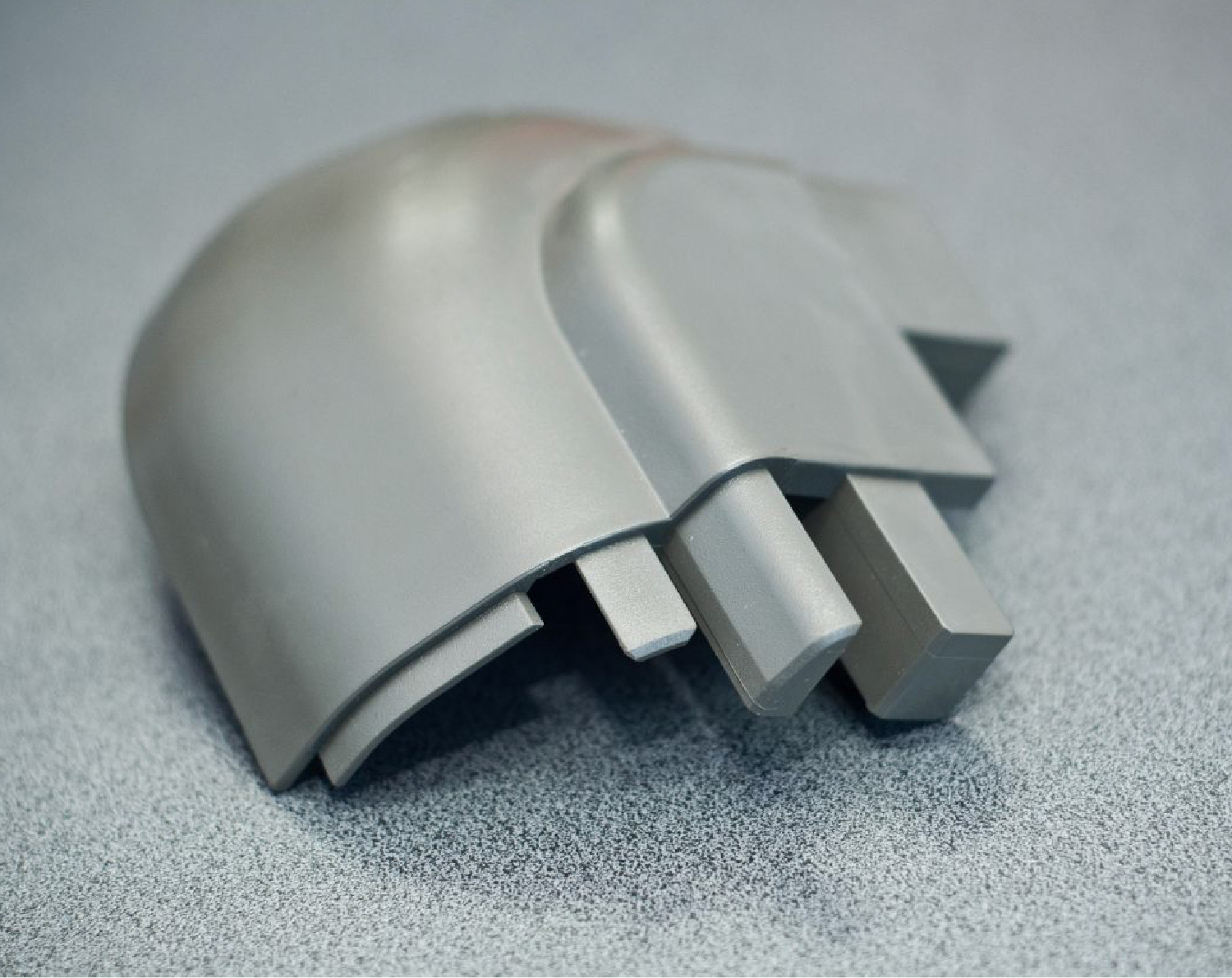

Tried and tested injection moulding technology

allows us to ensure accurate production of the smallest components as well as those of highly complex shapes. It is ideally suited for mass production – we can produce up to dozens of parts in a single cycle.

Continuous production optimisation through careful analysis and verification of production processes is our key to success. We support this with modern machinery that enables us to manufacture top-quality plastic products.

We also offer services in the following areas:

Packaging:

of manufactured parts

Assembly into sets

or subsets of finished products

Comprehensive logistics

D2D, Ex-works, consignment warehouses, JIT

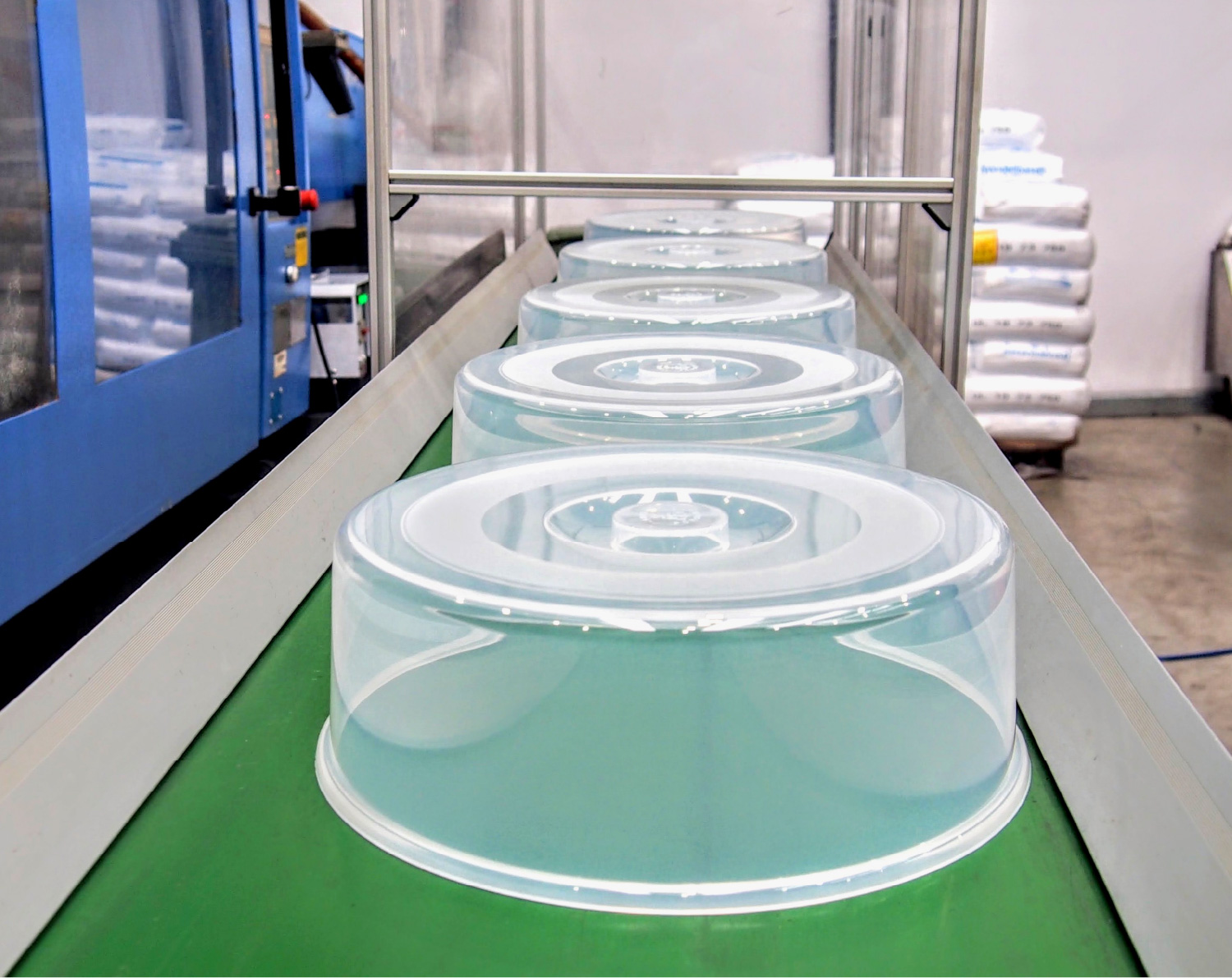

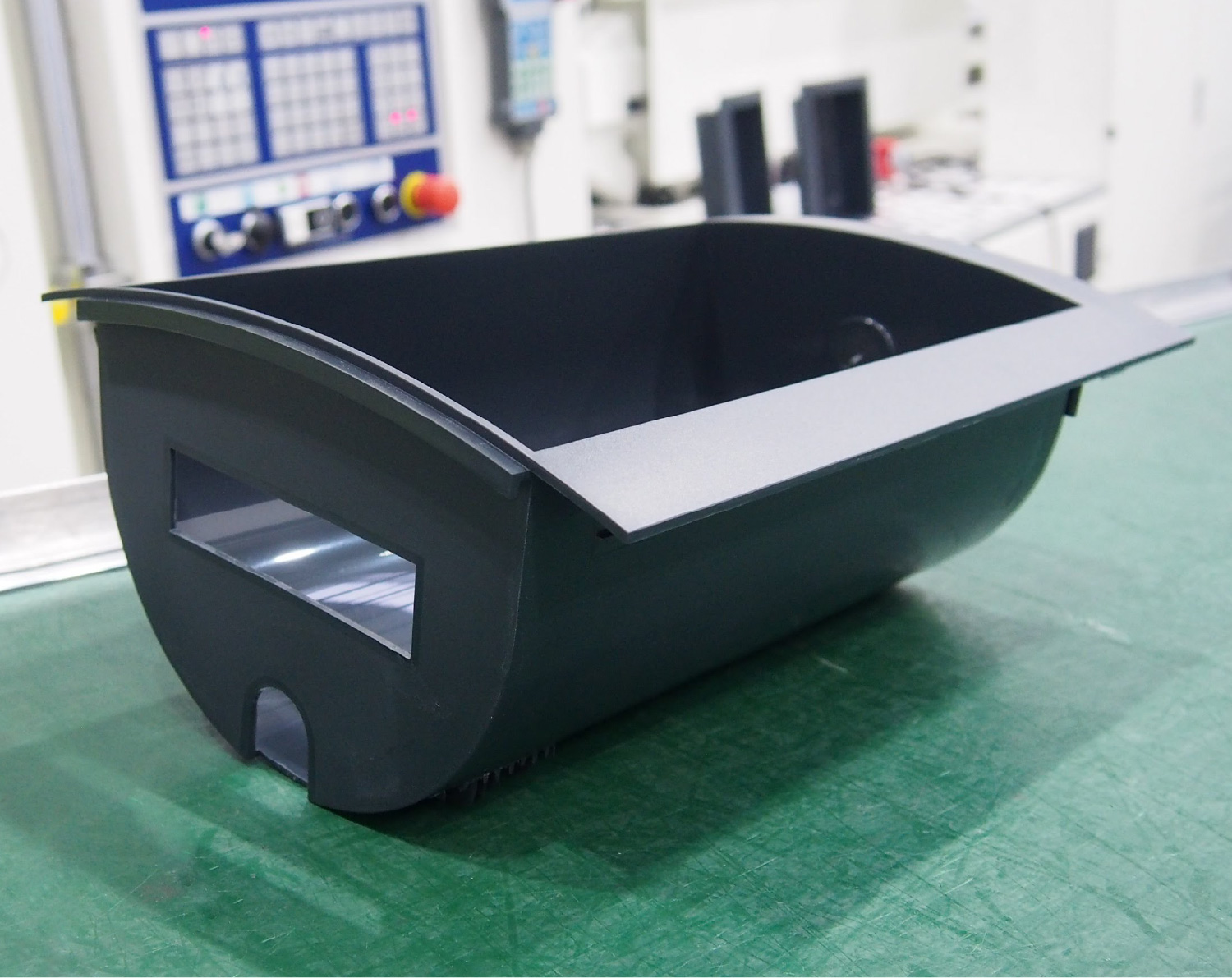

Check out sample elements we manufacture

MACHINE PARK

Our machine park allows us to carry out complex projects.

We have injection molding machines with a force of 100 to 1080 tons, ready to accommodate your order.

Thermoplastic processing stages:

1

Design

- product design

- 3D CAD modeling and visualization

- prototyping

- technical documentation development

- injection mould design and manufacturing

2

Technological Potential

- injection moulding machines with a closing force of 100 – 1100 T

- microprocessor controllers

- possibility to operate hydraulic and pneumatic cores

- machines with temperature controllers for moulds, hot runners and manipulators operating in three axes

3

Trials and Laboratory Testing

- material selection

- analysis of the correctness of material flow

- verification of the moulded part in terms of quality

- adjustments to technical and constructional assumptions

- testing of product functions

- ordering laboratory tests

- optimization of the production cycle

- production tests with the use of instrumentation entrusted by the customer

4

Project Finalization

- completion

- assembly

- logistics

Most frequently processed thermoplastics

PA6 – polyamide 6

is characterized by high endurance, rigidity, and abrasion resistance.

It displays physiological inertness, making it suitable for use in direct contact with food products. It also exhibits electro-insulating properties and high resistance to impact and chemical action.

Example Applications

Automotive

Electrical Engineering

Household Appliances

Furniture

Packaging

High-load Machine Parts

PA66 – polyamide 66

compared to PA6, it boasts superior mechanical endurance, rigidity, as well as thermal and chemical resistance.

It is distinguished by its antifriction and electro-insulating properties. It maintains dimensional stability even at high temperatures.

Example Applications

Automotive

Household Appliances

Electronics

Electrical Engineering

Furniture

Sport

PS – polystyrene

is a transparent material with a high surface gloss processed mainly by injection moulding.

It is ranked among the most important plastics used in the manufacture of consumer goods. It is distinguished by its high dimensional stability and electrical and dielectric properties.

Example Applications

Household Appliances

Packaging

Food industry

ABS – acrylonitrile-butadiene-styrene

this plastic excels in ease of processing, good dimensional stability and dirt resistance.

It has no side effects and is safe for health and the environment. As a result, it is used in the manufacture of toys and medical and pharmaceutical products.

Example Applications

Household Appliances

Automotive

Medical industry

Pharmaceutical industry

PC – polycarbonate

it is used in the production of components for many industries due to its wide range of properties.

It is distinguished primarily by its high resistance to mechanical damage and UV radiation. It retains rigidity at low as well as high temperatures.

Example Applications

Household Appliances

Automotive

Construction industry

Electronics

PP – polypropylene

is a plastic distinguished by its extraordinary endurance, hardness, low water vapour permeability, as well as chemical agent resistance.

It is ideally suited for the production of the most complex details.

Example Applications

Automotive

Hydraulics

Food industry

Medical industry

Pharmaceutical industry

Furniture

PE – polyethylene

Polyethylene is a plastic characterized by high resistance to abrasion and chemical agents.

It is distinguished by high dimensional stability and excellent electrical insulating properties. This material is certified by the Polish National Institute of Hygiene, making it possible for polyethene products to come into contact with food.

Example Applications

Cosmetics industry

Construction industry

Household Appliances

Electronics

Packaging

PMMA – poly(methyl methacrylate)

it is a plastic that is distinguished by its transparency and gloss. It features high UV and scratch resistance.

Moreover, it is characterized by exceptional optical properties, rigidity and dimensional stability.

Example Applications

Automotive

Construction industry

Household Appliances

Optics

Lighting

PTFE – Teflon

boasts excellent properties such as a wide operating temperature range, high chemical resistance and low coefficient of friction.

It is classified as non-flammable and resistant to weathering and UV radiation.

Example Applications

Automotive

Construction industry

Medical industry

Chemical industry

The selection of a suitable material depends on the project assumptions and applications of the workpiece.

We remain available to our customers and serve with our experience also in the appropriate material selection.

We use the most frequently processed thermoplastics and those more specific with the various fillers.

What can we do for you?

01

Concept and Design

Our designers develop a design tailored to your individual needs.

02

Fabrication

Our modern machinery allows us to carry out even the most complex projects.

03

Delivery and Installation

We work with reputable suppliers of raw materials so we can provide you with the highest quality materials.